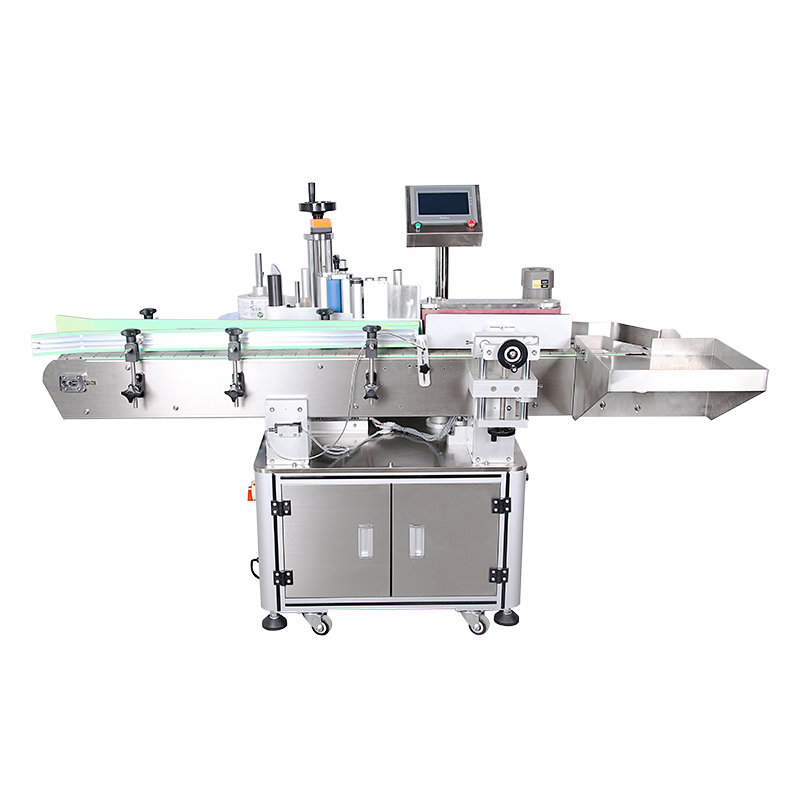

OEM manufacturer Automatic Round Bottle Labeling Machine - Real-time Printing and Side Labeling Machine – Feibin

OEM manufacturer Automatic Round Bottle Labeling Machine - Real-time Printing and Side Labeling Machine – Feibin Detail:

Real-time Printing and Side Labeling Machine

Machine Description:

1. Equipped with Zebra PAX Series print engine

2. Optional pneumatic,sweep labeling,corner labeling and other labeling methods, to satisfy different occasions and objects real-time printing&labeling requirement.

3. Universal joint structure of the labeling head, effectively correct labeling accuracy, and the unique light touch response and recoil function can keep product from collision.

4. The vacuum range can be adjusted to suit for different label sizes.

5. Independent stand install easily, vertical and horizontal adjustment structure can setting labeling location efficiently.

6. Exclusive side opening labeling structure,convenient for ribbon replacing and print head cleaning.

7. Flexible tag editing software, Compatible with most Chinese/English label editing tools, editing printed content has great flexibility.

8. Connecting function, connecting with the main system through Ethernet, achieving the purpose of real-time management and system integration, no need to work with a control computer.

9. Applying world-famous imported electrical components to ensure the machine’s stability and reliability.

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

Technical Parameters:

◆ Labeling accuracy (mm): ± 1.5mm

◆ Labeling speed (pcs / h): 360~900pcs/h

Applicable Product size: L*W*H: 40mm~400mm*40mm~200mm*0.2mm~150mm

◆ Suitable label size(mm) : Width: 10-100mm, Length: 10-100mm

◆ Power supply: 220V

◆ Device dimensions (mm) (L × W × H): customized

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of OEM manufacturer Automatic Round Bottle Labeling Machine - Real-time Printing and Side Labeling Machine – Feibin , The product will supply to all over the world, such as: Holland, Libya, Vancouver, Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!