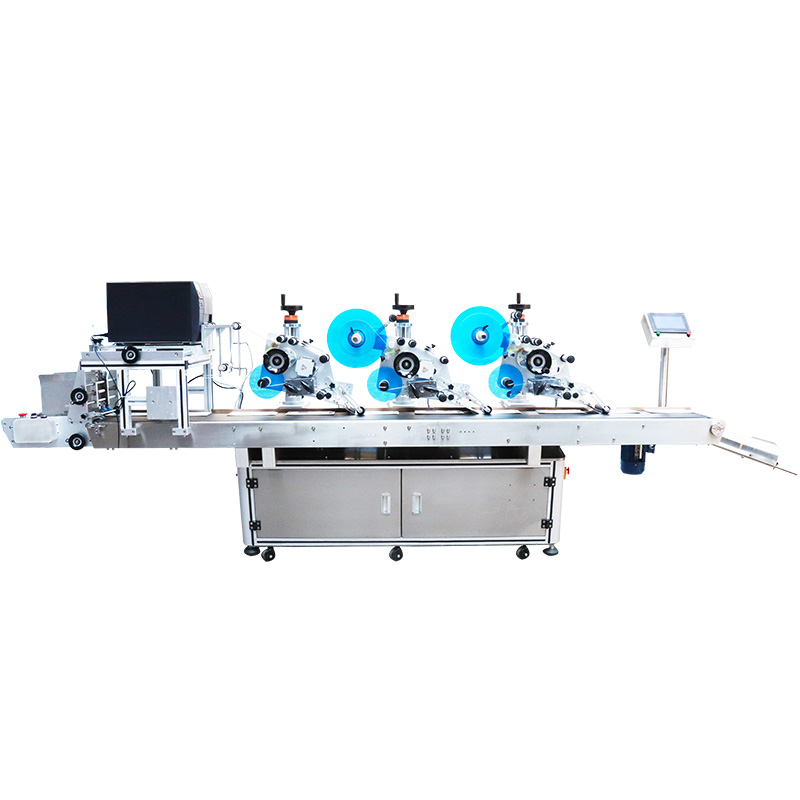

Good User Reputation for Automatic Labeller - FK813 Automatic Double Head Plane Labeling Machine – Fineco

Good User Reputation for Automatic Labeller - FK813 Automatic Double Head Plane Labeling Machine – Fineco Detail:

25-250ml/30-300ml/50-500ml Liquid Filling Machine

Machine description:

FK813 automatic dual-head card labeling machine has additional functions to add options: optional color band coding machine can be added to the label head, and the production batch, production date and expiration date can be printed at the same time. Reduce packaging process, greatly improve production efficiency, special label sensor.

The FK813 automatic dual-head card labeling machine has simple adjustment methods, high labeling accuracy and good quality, and it is difficult to see the error with the naked eye. Support custom labeling machine according to the product.

Technical Parameters:

| Parameter | Data |

| Labeling accuracy(mm) | ±1(errors caused by product and label are not concerned) |

| Labeling speed(pcs/min) | 40 ~ 80(Influenced by size of product and label size) |

| Suit products size(mm) |

L(W): ≥10; H: ≥0.2 Can be customized |

|

Suit label size(mm) |

L: 6 ~ 250; W(H): 15 ~ 130 |

| Voltage | 220V/50HZ(Can be customized) |

| N.W (KG) | ≈180 |

| G.W(KG) | ≈200 |

| Power(W) | 220V/50(60)HZ; |

| Serve | Lifetime technical service, one year warranty |

| Label Specification | Adhesive sticker, transparent or opaque |

| Operating personnel | 1 |

| Machine model number | FK813 |

Work Process:

Working Principle: The sensor detects the passing of the product and sends back a signal to the labeling control system. At the appropriate position, the control system controls the motor to send out the label and attach it to the product to be labeled. The attaching action of a label is completed.

Labeling Process: Operation process: put the product -> separate and transport the product (automatically realized by the equipment) -> labeling (automatically realized by the equipment) -> collect the labeled products (automatically realized by the equipment) -> take away the products.

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

The above label production needs to be combined with your product. For specific requirements, please refer to the results of communication with our engineers!

Product detail pictures:

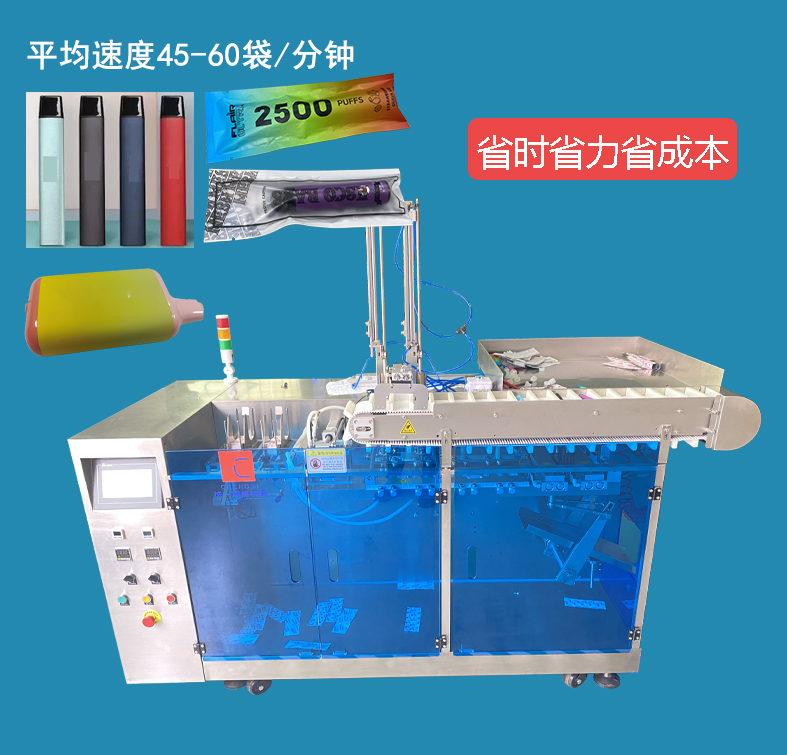

Related Product Guide:

Often customer-oriented, and it's our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for Good User Reputation for Automatic Labeller - FK813 Automatic Double Head Plane Labeling Machine – Fineco , The product will supply to all over the world, such as: Borussia Dortmund, San Diego, Tanzania, We've been always creating new technology to streamline the production, and give products with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We are going to present our best service to satisfy all your needs! Remember to contact us right away!

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.