Factory wholesale Small Scale Bottle Filling Machine - 6 nozzle liquid filling capping labeling machine – Fineco

Factory wholesale Small Scale Bottle Filling Machine - 6 nozzle liquid filling capping labeling machine – Fineco Detail:

6 nozzle liquid filling capping labeling machine

Machine Description

Applied Range: And material contact material imported 304 l material, no particles can be all kinds of corrosive resistant low viscosity fluid, such as: all kinds of reagents (medicine oil, wine, alcohol, eye drops, syrup), chemicals (solvents, acetone), oil (feed oil, essential oils, cosmetics (toner, makeup water, spray), food (high temperature resistant to 100 degrees, such as milk, soy milk), beverages, fruit juice, fruit wine, spices, soy sauce vinegar, sesame oil, etc without granular liquid;High and low foam liquid (nursing liquid, cleaning agent)

Filling of food, medical,cosmetic,chemical and other bottle liquids. Plus: wine, vinegar, soy sauce, oil, Water, etc.

Widely used in food, cosmetic, chemical, pharmaceutical and other industries.It can work alone or connect to production line.

Support customization.

Machine Description:

1. The whole line adopts advanced human-computer interface, operation parameters can be stored and adjusted, fault can be displayed, and it is easy to use;

2. The whole line is made of stainless steel and aluminum alloy, with a beautiful appearance;

3. The filling machine is safe and easy in operation, and can control the illing amount according to the time, and has a wide compatible range;

4. The whole line equipment has a reasonable structure layout, which is easy to disassemble and clean, and makes it easier in care and maintenance;

5. All the contact materials of the filling machine are made of 316 stainless steel, which is of good acid and alkali resistance and corrosion resistance;

6. The cap- screwing machine may be equipped with a vibrating disk, which can cap and uncap automatically, and the cap dropping track, capping head and bottle gripper adopt hand wheel control, which is convenient and simple.

7. The cap- -screwing machine can adapt to bottles of various specifications within scope of application by adjusting the tightness of gripper belt and the height of capping head without replacing parts.

8. The labeling machine adopts the new step drive,the speed of labeling is fast,and the labeling performance is stable.

Fully Automatic Multi-function Cap Screwing Machine

applied range: This equipment is used in food and beverage, pesticide and fertilizer, chemical industry plastic bottle glass bottle automatic hanging cap screw, straight line hanging cap preturning cap, can be applied to a variety of bottle, bottle change simple and fast, high production efficiency.

Performance Feature:

1. Full automation, in line with GMP requirements, high yield.

2. The machine can be operated by a single machine or used with the whole line.

3. It can be customized as required.

4. Applicable to a variety of bottle types. When the cap screw reaches the time of cap screw, the cap will stop automatically to protect the cap and bottle from damage.

Six – head magnetic pump automatic filling line

Parameter Configuration:

1.Metering method: Time and speed adjustment, suitable for almost all liquid products.

2.the size of the container, the container phi 20-30-350 mm 160 mm tall

3. packaging, weight, more than 2 g

4.Packing precision: Packing weight≤100g deviation≤±1g > 100g deviation≤±1% (test is based on water)

5.the packing speed: 25-60 cans/min (according to the nature of the bottle and filling liquid, 6 head filling machine, 300 ml, for example, 2000-2500 bottles per hour)

6.power supply: single-phase 220 v, 50 hz

7.the weight: 150 kg

8. the machine power: 1Kw

9. machine volume: 2000×1000×1400mm

10. magnetic pump flow range 10-5500 ml/min (take water as an example). Each working pump is separately controlled. The test is based on sending sample bottles.

11. Filling volume: 10-2000ml

Technical Parameters:

1. Model: HM – GJC – 16

2. Suitable cap shape: Plastic, metal round cover, pump head cover, duck mouth cover, etc

3. The sealing height: 30-300CM

4. Sealing diameters: 16-70CM

5. Production speed: 20-50 bottles per minute

6. Operating voltage: AC220V 60Hz

7. Working air pressure: 0.4-0.6 MPa

8. Length width and height: 1920*74*160CM

9. Package size: 2002*82*176CM

10. Weight: 140KGS

Automatic electromagnetic induction aluminum foil sealing machine

Features: composite electromagnetic induction aluminum foil sealing technology is contemporary international recognized advanced seal technology, the non-contact heating to adapt to the characteristics of plastic (PP, PVC, PET, ABS, HDPE, PS, DURACON) glass bottles and various sealing compound plastic hose and so on, is the pharmaceutical, food, oil, cosmetic, household, agrochemical bottled sealing the most advanced technology, walk in the forefront of industry technology level core elements adopt international famous brand, products more strict inspection, so the quality is stable and reliable.

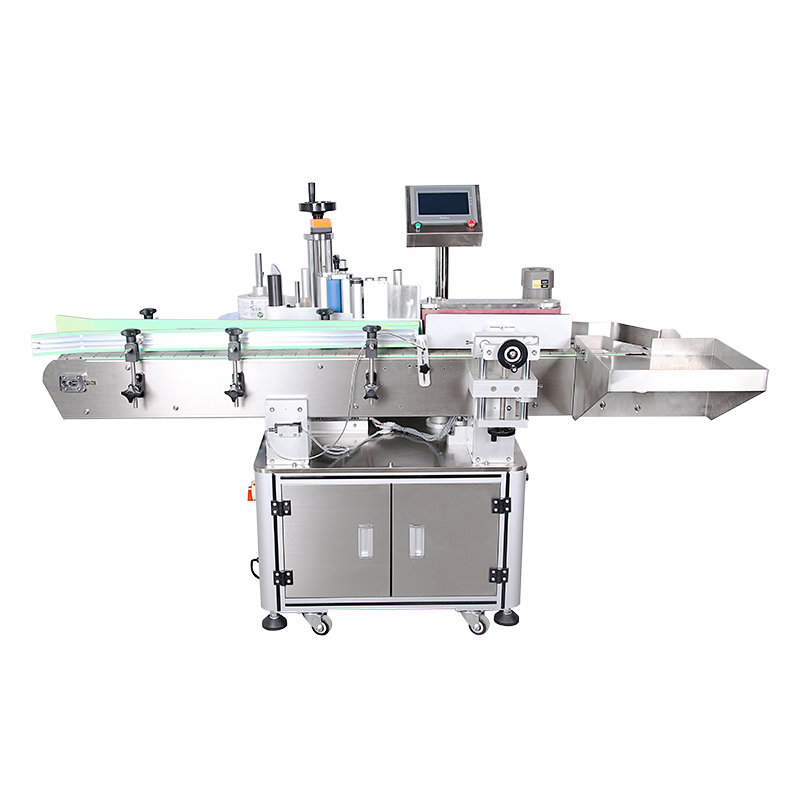

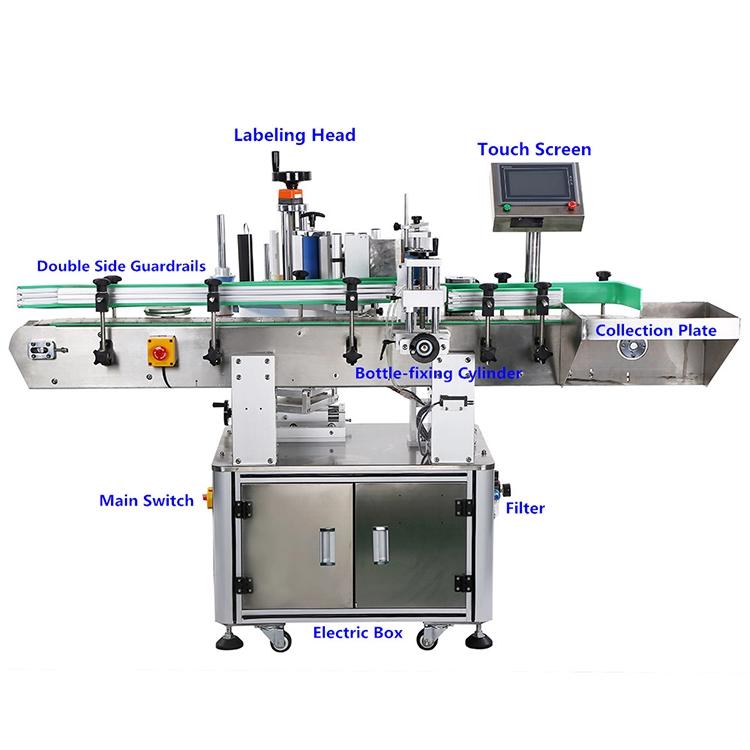

Automatic round bottle labeling machine

Suitable for round bottle labeling, can do single-labeling and double labeling, the labeling position can beadjusted casily. Widely used in cosmetics, food, pharmaceuticals, disinfectant and other industries.

Key technical parameters:

Labeling accuracy: ±1mm (excluding product and label errors);

Speed of labeling (PCS /min) : 25 ~ 60 pieces /min (related to product and label size);

Suitable product size: (for round bottle) and height: diameter: 25mm ~ 140mm Height: 25mm ~ 300mm

Applicable label size: Length: 20mm ~ 380mm ;Width (width of backing paper) : 20mm ~ 130mm;

Machine size: about 1950mm×1200mm×1530mm (length × width × height);

Power supply: 220V 50/60Hz;

Machine weight: about 185Kg.

Product detail pictures:

Related Product Guide:

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Factory wholesale Small Scale Bottle Filling Machine - 6 nozzle liquid filling capping labeling machine – Fineco , The product will supply to all over the world, such as: Slovenia, Rwanda, Monaco, With the advanced workshop, professional design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our products are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!