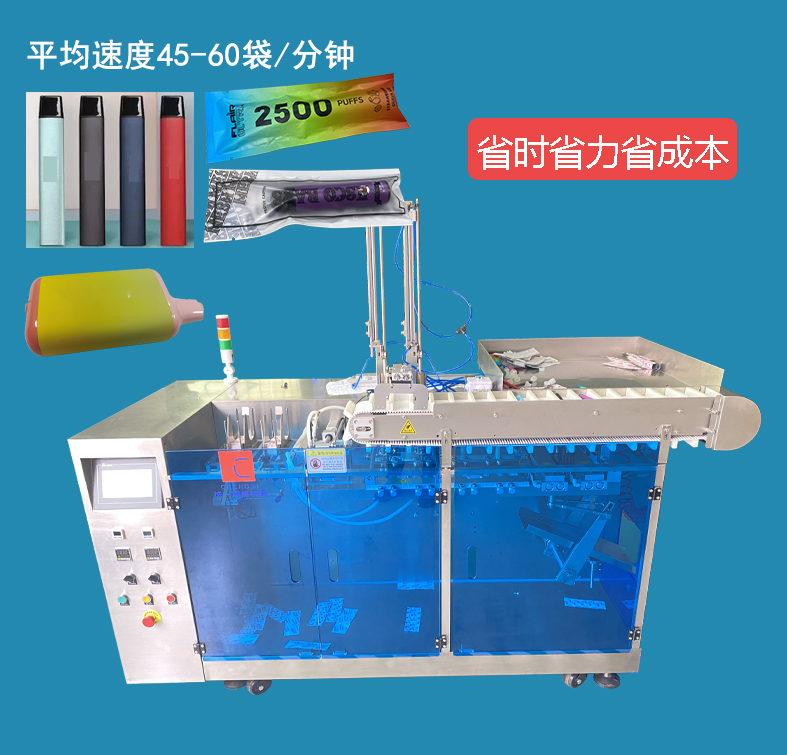

Factory wholesale Automatic Sleeve Sealer - FK839 Automatic Bottom Production Line Labeling Machine – Feibin

Factory wholesale Automatic Sleeve Sealer - FK839 Automatic Bottom Production Line Labeling Machine – Feibin Detail:

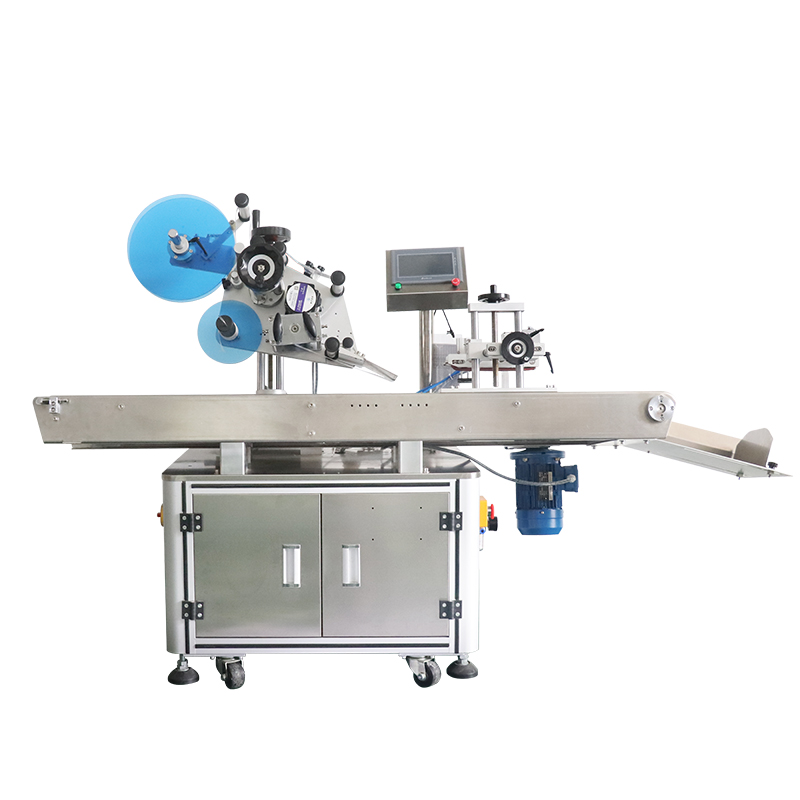

FK839 Automatic Bottom Production Line Labeling Machine

Machine Description:

FK839 Automatic Bottom Production Line Labeling Machine is suitable for products that require large output, with high labeling accuracy of ±0.1mm, fast speed and good quality, and it is difficult to see the error with the naked eye.

FK839 Automatic Bottom Production Line Labeling Machine covers an area of about 0.44 cubic meters

Support custom labeling machine according to the product.

Work Process:

working principle: The sensor detects the passing of the product and sends back a signal to the labeling control system. At the appropriate position, the control system controls the motor to send out the label and attach it to the labeling position of the product. The product passes the labeling roller, and a label The attaching action is completed.

Labeling Process:

Product (connected to the assembly line) —> product delivery —> product testing —> labeling.

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

Technical Parameters:

◆ Labeling accuracy (mm): ±1mm(errors caused by product and label are not concerned)

◆ Labeling speed (pcs / min): Step:40~150pcs/min Servo:50~200pcs/min (influenced by the size of the product and label)

◆ Applicable Product Diameter: No requirement (Depend on assembly line convey parameter.)

◆ Suitable label size(mm): length: 10mm~250mm; Width: 10mm~120mm

◆ Applicable power supply: 220V/50HZ

◆ Weight (kg): about 70kg

◆ Applicable standard roll Inner diameter (mm): φ76mm

◆ Applicable standard roll Outer diameter (mm): φ300mm

◆ Power (W): 300W

◆ Device dimensions (mm) (L × W × H): about 750mm ×700mm ×850mm

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Factory wholesale Automatic Sleeve Sealer - FK839 Automatic Bottom Production Line Labeling Machine – Feibin , The product will supply to all over the world, such as: Czech, Casablanca, Ukraine, We welcome you to visit our company & factory and our showroom displays various products and solutions that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to supply you with the best services. If you will need more information, please do not hesitate to contact us via E-mail, fax or telephone.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.