Factory supplied Plastic Label Maker Machine - FK909 Semi Automatic Double-sided Labeling Machine – Feibin

Factory supplied Plastic Label Maker Machine - FK909 Semi Automatic Double-sided Labeling Machine – Feibin Detail:

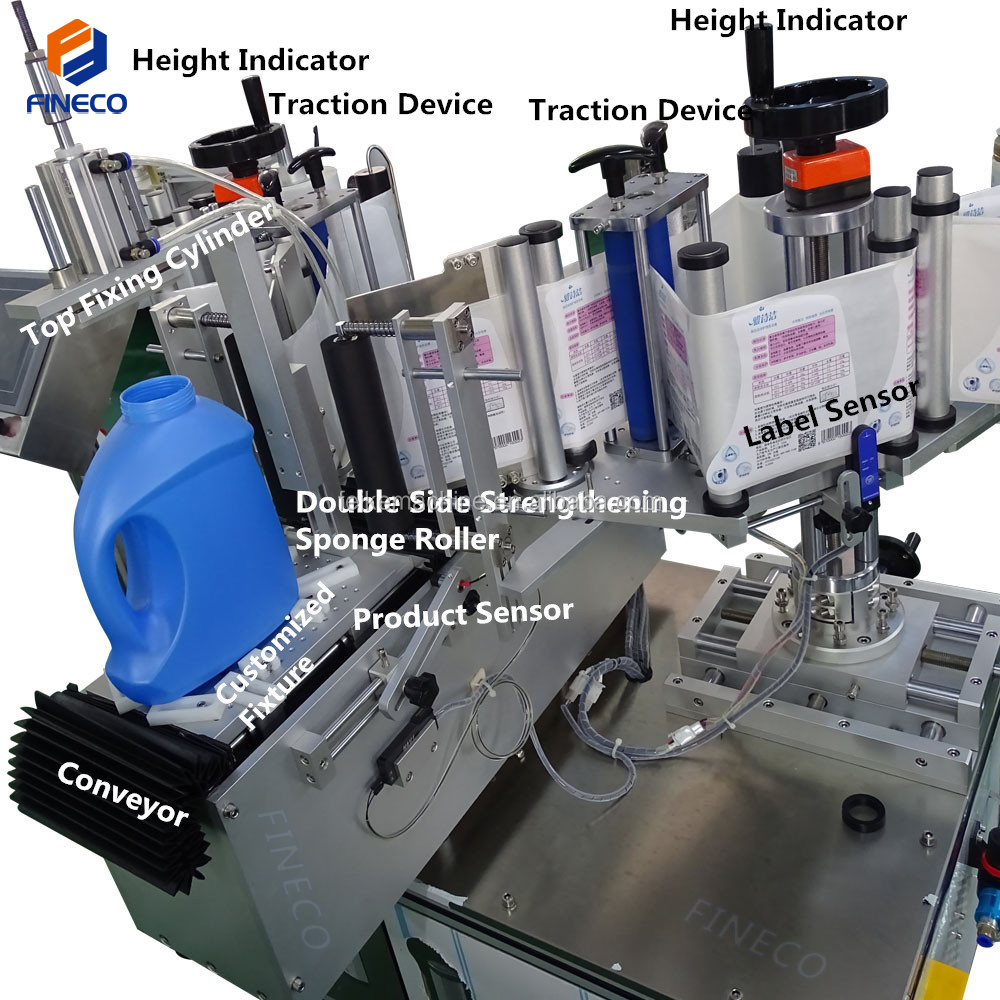

FK909 Semi Automatic Double-sided Labeling Machine

You can set video sharpness in the lower right corner of the video

Machine Description:

FK909 semi-automatic labeling machine has additional functions that can be added to the options: optional color band coding machine is added to the label head, and the production batch, production date and expiration date are printed at the same time. Reduce packaging process, greatly improve production efficiency, special label sensor.

FK909 semi-automatic labeling machine has simple adjustment method, high labeling accuracy of ±0.5mm, good quality, and it is difficult to see the error with the naked eye.

FK909 semi-automatic labeling machine covers an area of about 0.35 cubic meters

Support custom labeling machine according to the product.

Technical Parameters:

| Parameter | Date |

| Label Specification | Adhesive sticker,transparent or opaque |

| Labeling Tolerance | ±1mm(errors caused by product and label are not concerned) |

| Capacity(pcs/min) | 15 ~ 30(According to product size) |

| Suit bottle size(mm) | L:40~400; W:40~200 H:0.2~150;Can be customized |

| Suit label size(mm) | L:6~150;W(H):15-130 |

| Machine Size(L*W*H) | ≈1300*1200*1400(mm) |

| Pack Size(L*W*H) | ≈1350*1250*1450(mm) |

| Voltage | 220V/50(60)HZ;Can be customized |

| Power | 990W |

| N.W(KG) | ≈150.0 |

| G.W(KG) | ≈170.0 |

| Label Roll | ID:>76mm; OD:≤280mm |

Working Principle:

This part of the principle for our own research and development, if interested, welcome to consult.

Label Specification:

1. Feeding: Put product on the fixture.

2. Transmission: the conveyor sends the product forward and backward.

3. The product sensor sends product signal and PLC outputs labeling signal.

4. Labeling.

5. Strengthening: the sponge on the 2 sides press the labels to make they stick tighter.

6. Collection: Get the ready labeled product Out.

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

The above label production needs to be combined with your product. For specific requirements, please refer to the results of communication with our engineers!

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and with the superior quality products, favorable price and good after-sales services, we try to win every customer's trust for Factory supplied Plastic Label Maker Machine - FK909 Semi Automatic Double-sided Labeling Machine – Feibin , The product will supply to all over the world, such as: Holland, Norwegian, Marseille, Our products are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.