Factory making Single-Sided Labeling Machine For Gasoline Bottles - FK839 Automatic Bottom Production Line Labeling Machine – Feibin

Factory making Single-Sided Labeling Machine For Gasoline Bottles - FK839 Automatic Bottom Production Line Labeling Machine – Feibin Detail:

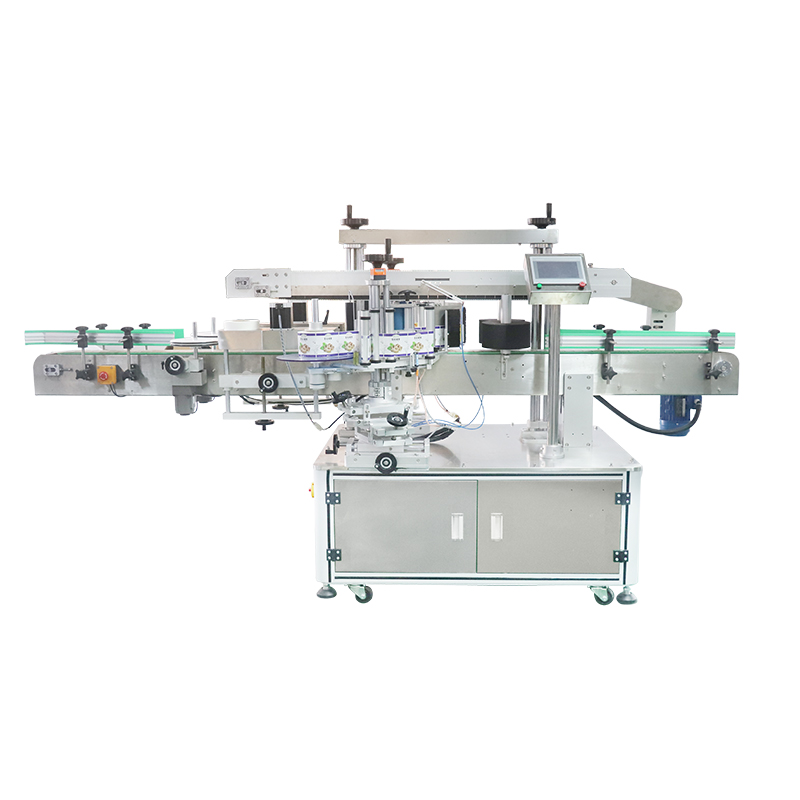

FK839 Automatic Bottom Production Line Labeling Machine

You can set video sharpness in the lower right corner of the video

Machine Description:

FK839 Automatic Bottom Production Line Labeling Machine is suitable for products that require large output, Can be directly installed or connected to the production line, with high labeling accuracy of ±0.1mm, fast speed and good quality, and it is difficult to see the error with the naked eye.

FK839 Automatic Bottom Production Line Labeling Machine covers an area of about 0.44 cubic meters

Support custom labeling machine according to the product.

Technical Parameters:

| Parameter | Data |

| Label Specification | adhesive sticker, transparent or opaque |

| Labeling Tolerance(mm) | ±1 |

| Capacity(pcs/min) | 40 ~150 |

|

Suit product size(mm) |

L: 10~250; W:10 ~ 120. Can be customized |

| Suit label size(mm) | L: 10-250; W(H): 10-130 |

| Machine Size(L*W*H)(mm) | ≈700 * 650 * 800 |

| Pack Size(L*W*H)(mm) | ≈750*700*850 |

| Voltage | 220V/50(60)HZ;Can be customized |

| Power(W) | 300 |

| N.W (KG) | ≈70.0 |

| G.W(KG) | ≈100.0 |

| Label Roll | ID: >76; OD:≤280 |

Work Process:

working principle: The sensor detects the passing of the product and sends back a signal to the labeling control system. At the appropriate position, the control system controls the motor to send out the label and attach it to the labeling position of the product. The product passes the labeling roller, and a label The attaching action is completed.

Labeling Process:

Product (connected to the assembly line) —> product delivery —> product testing —> labeling.

Label Production Requirements

1. The gap between the label and the label is 2-3mm;

2. The distance between the label and the edge of the bottom paper is 2mm;

3. The bottom paper of the label is made of glassine, which has good toughness and prevents it from breaking (to avoid cutting the bottom paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 280mm, arranged in a single row.

Product detail pictures:

Related Product Guide:

Our business promises all users of the first-class items and the most satisfying post-sale company. We warmly welcome our regular and new prospects to join us for Factory making Single-Sided Labeling Machine For Gasoline Bottles - FK839 Automatic Bottom Production Line Labeling Machine – Feibin , The product will supply to all over the world, such as: Czech, Belgium, Philippines, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.