2021 High quality Bottle Screw Capping Machine - FK Eye drops filling production line – Feibin

2021 High quality Bottle Screw Capping Machine - FK Eye drops filling production line – Feibin Detail:

FK Eye Drops Filling Production Line

Requirements: equipped with bottle cap ozone disinfection cabinet, automatic bottle unscramble, air washing and dust removal, automatic filling, automatic stoppering, automatic capping as an integrated production line (capacity per hour/1200 bottles, calculated as 4ml)

Provided by the Customer: the bottle sample, inner plug, and aluminum cap are shown in the figure below:

Process Flow:

1. Manually put the bottles and lids in the ozone disinfection cabinet for sterilization →

2. Manually put the sterilized bottles into the bottle unscrambler, put the inner stopper on the unscrambled cover tray, and prepare the materials and camellia oil for the automatic production line →

3. The production line automatically loads bottles→automatic blowing→automatic stoppering→automatic cap hanging→automatic capping→automatic output of finished products→manual packing.

Equipment Composition:

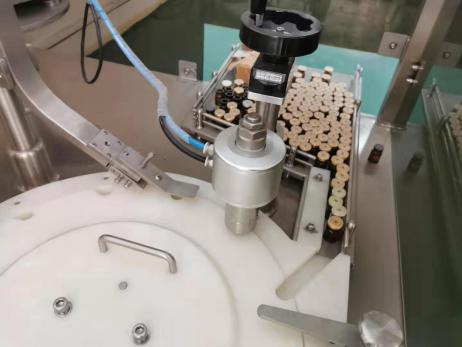

This equipment includes an ozone disinfection cabinet for bottles and caps; disc sorting bottles; air washing and dust removal; camellia oil filling; vibrating disc stopper sorting machine; vibrating disc sorting cover machine; top stopper and lower cover capping mechanism, main star plate, Conveyor belt, finished product collection table, man-machine interface touch screen.

Equipment Layout and Installation Dimensions

Equipment parameters:

|

Equipment name |

4ml eye drops filling automatic production line |

|

Voltage |

AC220V 50HZ |

|

Power |

2KW |

|

Air pressure |

0.6mpa |

|

Applicable bottle mouth |

inner diameter 7mm applicable bottle height 35~50mm applicable bottle cap diameter 13.5mm |

|

Applicable filling range |

4ml |

|

Equipment weight |

680KG |

|

Installation size |

3000X1800X2200mm |

Device parameters:

|

Ozone production |

10mg/h |

|

A single lid sterilization |

can reach 5000~9000 (depending on the storage space) |

|

Equipment size |

1500X600X1600mm |

|

Weight: about |

150KG |

|

Voltage |

220v/1800W |

Work Process:

Core working principle: After the bottle separating mechanism separates the product, the sensor detects the product passing, and sends back a signal to the labeling control system. At the appropriate position, the control system controls the motor to send out the label and attach it to the product to be labeled. Product flow After the labeling device, the labeling drive drives the product to rotate, the label is rolled, and the attachment of a label is completed.

Operation process: put the product (can be connected to the assembly line) -> product delivery (equipment automatic realization) -> product separation -> product testing -> labeling -> labeling -> collection of labeled products.

After-sales Service:

Supplier is responsible for domestic equipment installation and commissioning and personnel training;The buyer shall provide electric, gas and hydraulic support conditions and on-site coordination personnel.

The warranty period is one year. Paid technical services will be provided outside the warranty period.

Product detail pictures:

Related Product Guide:

We often stay with the principle "Quality Very first, Prestige Supreme". We have been fully committed to supplying our consumers with competitively priced high-quality goods, prompt delivery and skilled provider for 2021 High quality Bottle Screw Capping Machine - FK Eye drops filling production line – Feibin , The product will supply to all over the world, such as: Liberia, Argentina, UK, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we've been committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have now passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,